Pressure printing is a relief printmaking process that uses built up layers of paper or card to create greater impression on a printing block. A type-high block, usually made of plexiglass, is put into the press and inked up with your favorite color.

A flexible printing plate is inserted behind the printing paper and run through the press. The thicker areas provide more pressure and make darker marks. The press is reinked and the next run of the print is made.

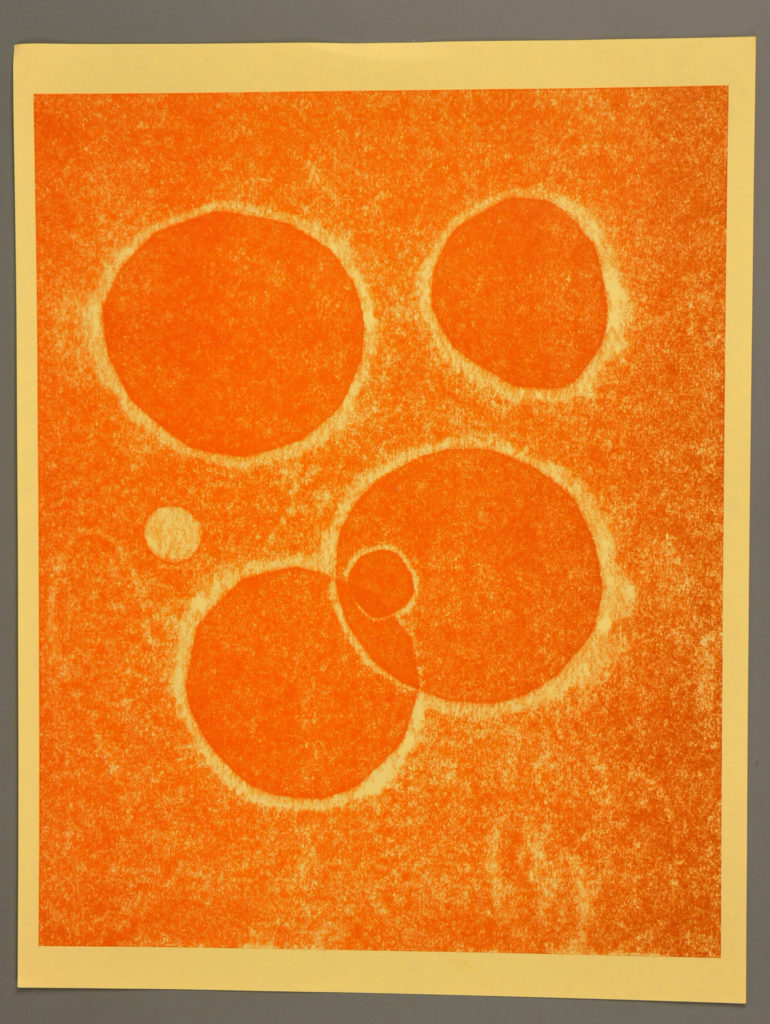

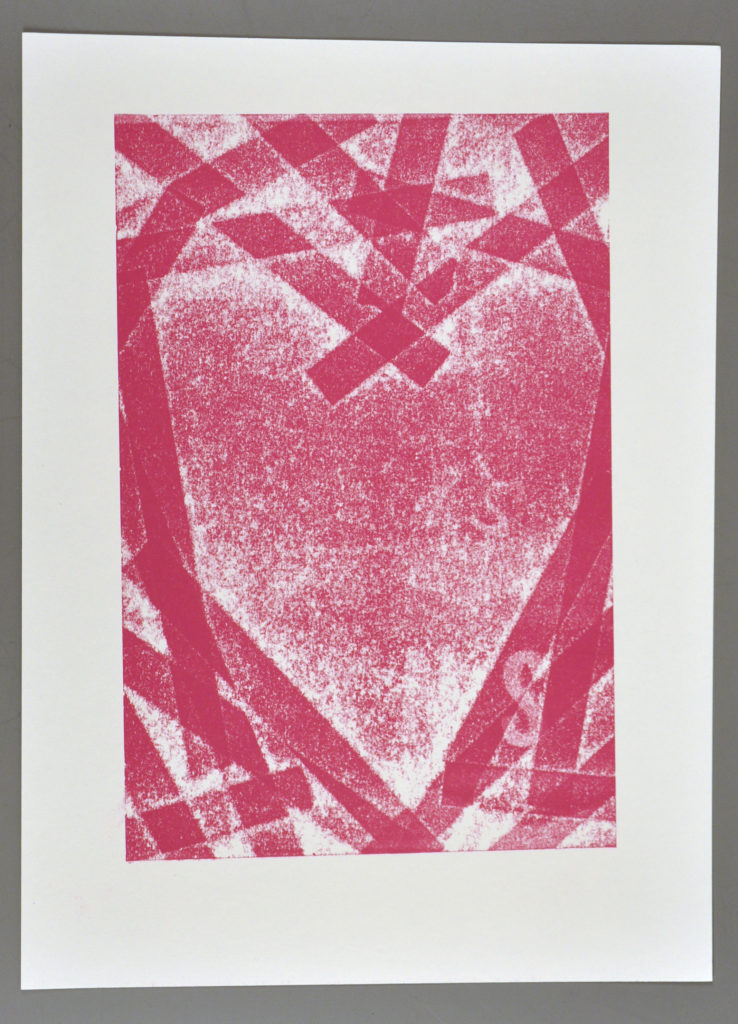

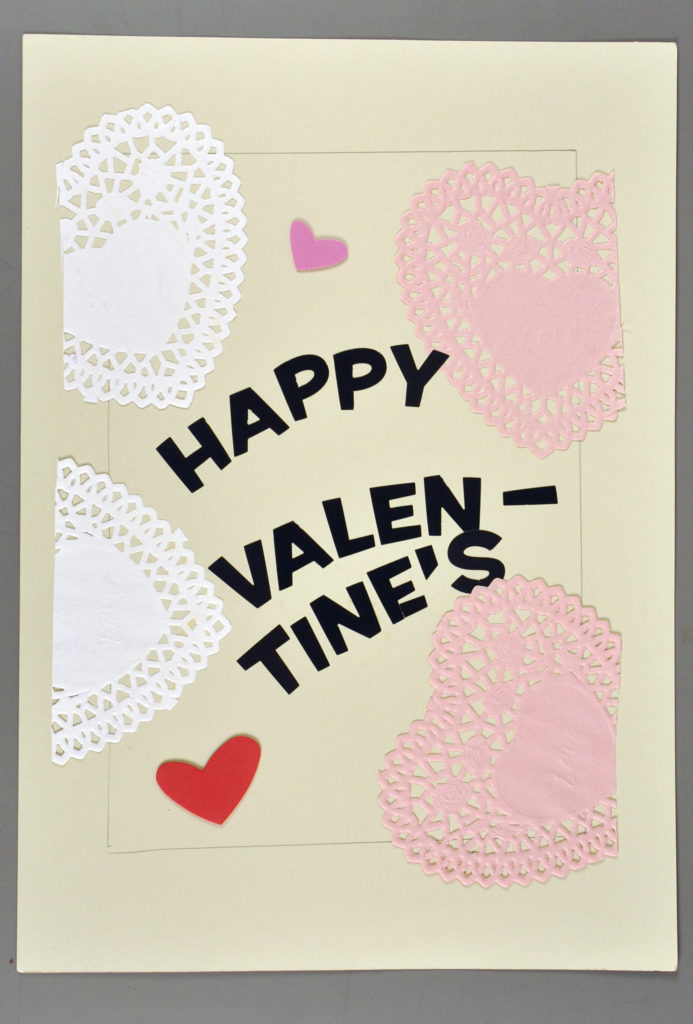

The printing plate is based on a piece of paper or mylar. In the following images, a sheet of card stock has been built up with layers of paper, some separate, some stacked up.

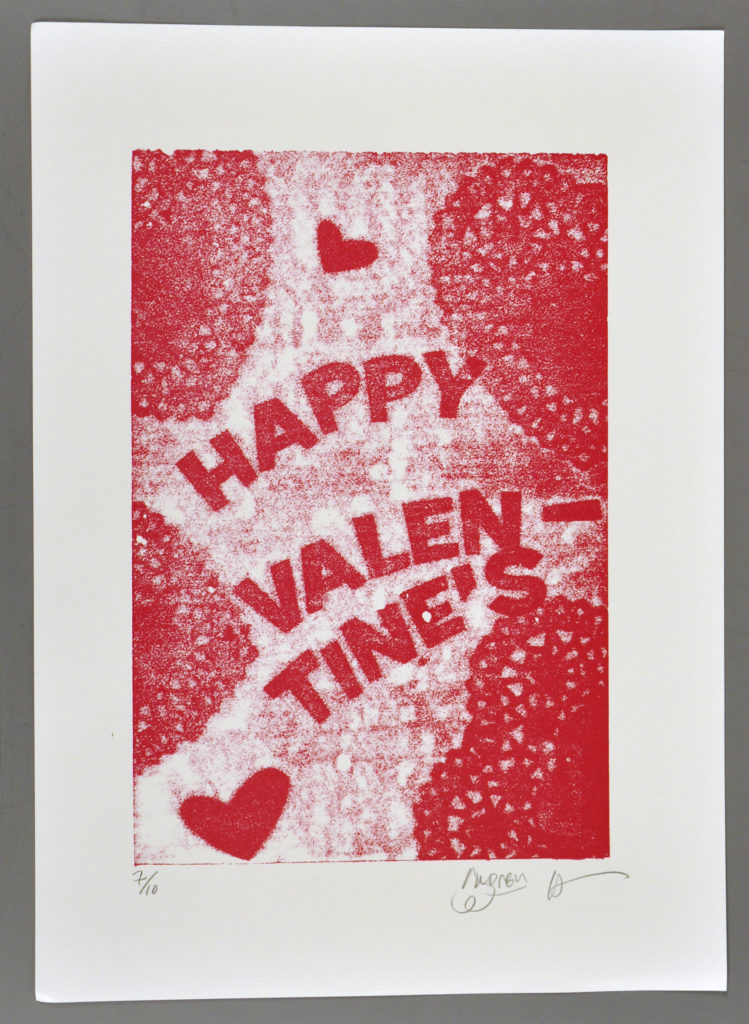

Here are some examples of pressure printing plates and the prints that they made.

One nice thing about pressure printing is that you can add text to your plate right-reading using stickers or cut letters, and the text will print correctly, as you see here.

You can experiment with paper, cut materials, and other materials, just be sure not to get too thick with your layers. Thick areas will create voids or unprinted spots nearby. When making your plate, you can print and alter before moving along with the final printing. If you’re not near the press, doing a rubbing with crayon will give you the general idea.

More information can be found at the Letterpress Commons website, here.